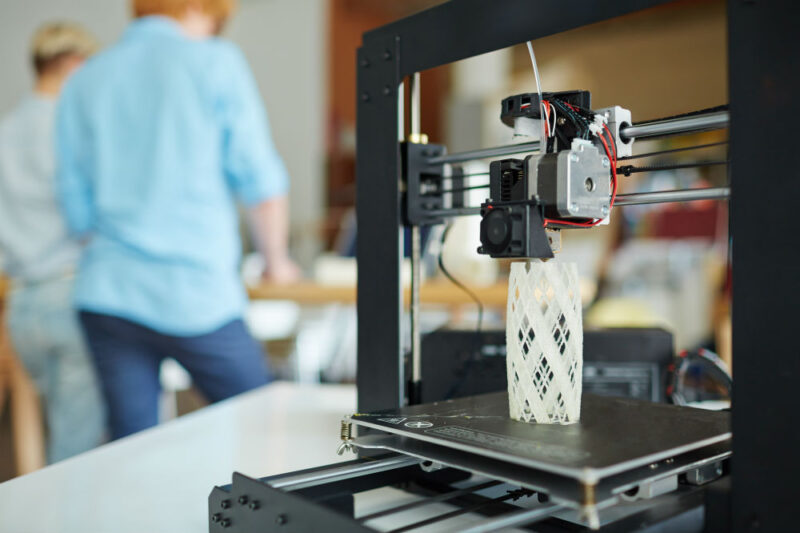

A 3D printer is an amazing machine that can print out objects from digital files. And, not only can you print out objects using a standard desktop 3D printer, but you can also use a special type of 3D printer called a “foam printer” to print out architectural foam moldings.

What is architectural foam molding?

Architectural foam molding (A/M) is a type of manufacturing that uses foam to create 3D shapes. It is used to create products such as chair backs, door panels, and window frames.

A/M is usually done with a D-printer. You first print the patterns for the molding onto the foam. The printer prints the patterns in layers, so that you can create detailed parts. Then you use a tool to smooth out the bumps on the pattern. This allows you to create a perfect 3D shape from the foam.

A/M is a very precise process. You need to make sure that your printable patterns are absolutely accurate. If they are not, your finished product will not be accurate or fit well. A good way to ensure accuracy is to test your patterns online before printing them out. This will help you to avoid any surprises during the printing process.

A/M is a type of foam insulation that is used to build structures or buildings with less material waste. It has been used in construction since the 1970s and has since become one of the most popular materials for insulation due to its low cost, easy installation, and high energy efficiency.

A/M is a two-dimensional product that is made up of small cells that are interconnected. The cells are filled with a hot, foamy mixture and then heated until the cells expand. This process forms a hard, durable foam that can be used to insulate buildings or structures.

The most common types of A/M are closed cell and open cell. Closed cell foam is made up of small cells that are tightly sealed together. This type of foam is ideal for use in cold environments because it traps heat better than open cell foam. Open cell foam, on the other hand, is made up of larger cells that allow air to flow between them. This type of foam is best suited for warm environments because it allows heat to escape easily.

It can be installed using a variety of methods. The most popular way is to use a thermal expansion joint compound to attach the foam to the substrate. This method is typically used when installing open cell foam because it allows for greater flexibility and accuracy when installing the foam.

It is a cost-effective way to insulate buildings or structures. It has a high energy efficiency rating, and it can be installed quickly and easily using a variety of methods.

The Different Types of 3D Printers

Architectural foam moldings are becoming increasingly popular, especially in the residential and commercial construction industries. However, many homeowners and business owners don’t know how to create these molded pieces using a 3D printer.

There are a few different types of 3D printers that can create architectural foam moldings. These 3D printers include desktop 3D printers, industrial 3D printers, and D-type 3D printers.

Desktop 3D printers are the most common type of 3D printer used by homeowners and business owners.

They are small and easy to use, and they can be placed on a desk or countertop.

Industrial 3D printers are larger than desktop 3D printers and they are used by businesses and professionals in the construction industry. They are also more expensive than desktop 3D printers.

However, D-type 3D printers are the best option for creating architectural foam moldings. They are smaller than industrial 3D printers and they are more affordable than both desktop and industrial 3D printers.

If you want to create architectural foam moldings using a 3D printer, there is no one perfect printer for the job. You need to find a printer that is suited to your specific needs.

Some things to consider when choosing a 3D printer for A/M include the following:

- The size of the 3D printer.

- The type of 3D printer.

- The cost of the 3D printer.

- The availability of the 3D printer.

- The ease of use of the 3D printer.

- The quality of the 3D printer.

- The speed of the 3D printer.

- The warranty of the 3D printer.

Composites allow you to print extremely strong and durable objects with little to no waste. This is essential for creating architectural foam moldings, which often require extremely dense and strong pieces of foam.

How to Create an Architectural Foam Molding in a 3D Printer

First, you will need to download the files for the 3D printing process. Once you have downloaded the files, you will need to print the objects on a 3D printer.

Next, you will need to cut out the objects using a Dremel tool or a saw. You can use these objects to create your architectural foam moldings.

Finally, you will need to attach the objects to a support structure. You can do this by using hot glue or another type of adhesive and you can visit hotmelt.com for suitable options. Once the object is attached, you can finish up the 3D printing process by adding additional details and colors.

Overall, this process is relatively easy to follow. You will need some basic tools and knowledge to complete the project.

Conclusion

Yes, you can create architectural foam moldings in a 3D printer. So now after reading this post, you’re fully informed on how to create foam moldings on a 3D printer, so what are you waiting for? Start printing now!

FAQ

1. How much does it cost to make things with a 3D printer?

3D printers can range in price from around $1,000 to over $10,000.

2. Can a house be built by a 3D printer?

Yes, a house can be built by a 3D printer.

3. How durable are 3D printed houses?

3D printers are not 100% durable, but they are much more durable than traditional construction methods. 3D-printed houses can last anywhere from a few years to many decades with proper care.