Cooling towers are one of our great feats and these can be seen around large factories that require big cooling solutions for the job they do.

Cooling towers can be found in different sizes from smaller and thin ones to large and thick ones, all depending on the cooling power needed to the factory it is located next to. The shape of those is pretty remarkable and easy to remember – they have a wide base, slim middle body and wide top.

They are designed as an hourglass and it is with a great purpose. What is also easy to remember from these cooling towers is the drift coming from the top which many of us think is smoke but it is evaporated cooling water.

Now these types of cooling towers are used in certain industries and they are rather expensive to build and they require a whole lot of maintenance. If you want your business to flow as planned all the parts of your industry have to be in sync and well maintained so problems and mistakes are avoided.

As far as maintenance of these towers goes it is not something you can do by yourself, you have to hire a professional cooling tower engineering company that can get the job done and guarantee the quality of their work.

Now without any further ado here are some of the maintenance mistakes that can be made with cooling towers, and here are the ways to avoid them as well.

1. Contamination

Since we know what these towers are for and since we know the basics of how they operate you have to know that there will be severe contamination that can cause it to work ineffectively. The contamination is due to all the heat and humidity that are always in these towers, and those are a breeding ground for biological growth lice bacteria. Since the water brings in many of the nutrients, combined with constant heat you get a lot of these bacteria that form a film of sorts that destroys the capability of cooling your tower had.

It will build up over time and deteriorate the effective cooling power which is bad. The solution is to seal any possible leaks of water inside the tower and to get the sample of water before and after treatment. If the water sample is bad, the treatment should be chlorine shock of the water source in 48 hours. If the results are the same repeat the treatment until the results of water samples are acceptable.

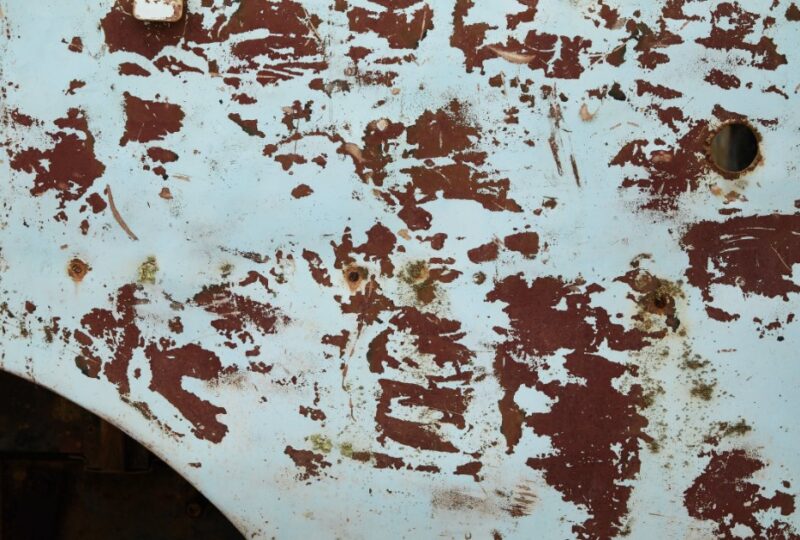

2. Corrosion

Now, whenever you have a combo of moist, humid, hot and cold flashes of water and metal parts the result is always corrosion. When you have a lot of water, chemicals like sodium, chlorine and many others found in our water supply they will over time eat away the metal piping, causing leaks all over that to diminish the cooling capabilities but also bring danger to the entire system falling apart due to corrosion.

Corrosion in the cooling towers is the inevitable meaning we can never get rid of it completely but there are ways to slow it down at least a bit. What you could do is utilize the three steps everyone knows about – applying the epoxy coating to your pipes or simply buying quality chiller tube coating and coatings for the tower. The next one is adding orthophosphate into the water that will aid in preventing corrosion at least for a while but it will bring up a whole other problem.

Orthophosphates are known to be a kind of aid for some microbiological species that again bring you to the problem of contamination. The last thing you can try is raising the pH of your water source to or close to 9.0. If you find a good balance between these three things you just might prolong the life of your cooling tower and postpone the corrosion a bit.

3. Clogging

Clogging is another problem that happens in cooling towers and it most commonly hits the fill. Clogging of cooling surfaces or even pipes can occur due to debris, dirt, dust or whatever else the water manages to bring inside the cooling tower. If you get stuck with clogged fill you will lose all of your cooling efficiency, over-burden certain elements of your cooling tower and lead to other malfunctions.

Not to mention that the electrical cost that will be too much simply because you can’t achieve the same efficiency with clogged surfaces. To avoid this, you need to treat the clogged areas with chlorine to clean them a bit, if you have to fill clogged up the best solution if cleaning doesn’t help is to swap it all or segments that are the worst, and exchange the nozzles if they are badly clogged up that even the cleaning doesn’t help.

4. Scaling

Another problem that occurs in cooling towers is scaling. Thanks to constant water flow through the piping as well as it evaporating in the top of the tower you will have a lot of scale buildup that will eventually diminish the efficiency of your tower and its parts. There are a lot of minerals that produce scaling but calcium is the number one culprit and it has to be treated accordingly or it will lead up to poor heat exchange in important places, and it will diminish the efficiency as well as increase the operational costs.

To prevent scaling you have to implement tube coatings made from polymers. These will effectively fight scaleing and the reason is that tube coating from polymers is highly conductive to heat meaning you will have all the efficiency you need but they will not allow calcium a surface to stick to and cause problems.

There are some procedures you can use to clean severe calcium buildup but the best advice is to use chiller tube coatings immediately or the first time you need to treat this problem.

So, we hope that we opened your eyes to these maintenance problems and that we showed you how to deal with them. The only thing to remember here is that professional companies that deal with the maintenance of these cooling towers already know this and they will surely do whatever they can to help you prevent any future problems. Choose your maintenance company wisely and your cooling towers will never lose their efficiency.